商铺名称:保定建信模具制造有限公司

联系人:冉经理()

联系手机:

固定电话:

企业邮箱:

联系地址:

邮编:

联系我时,请说是在五金机电网上看到的,谢谢!

商品详情

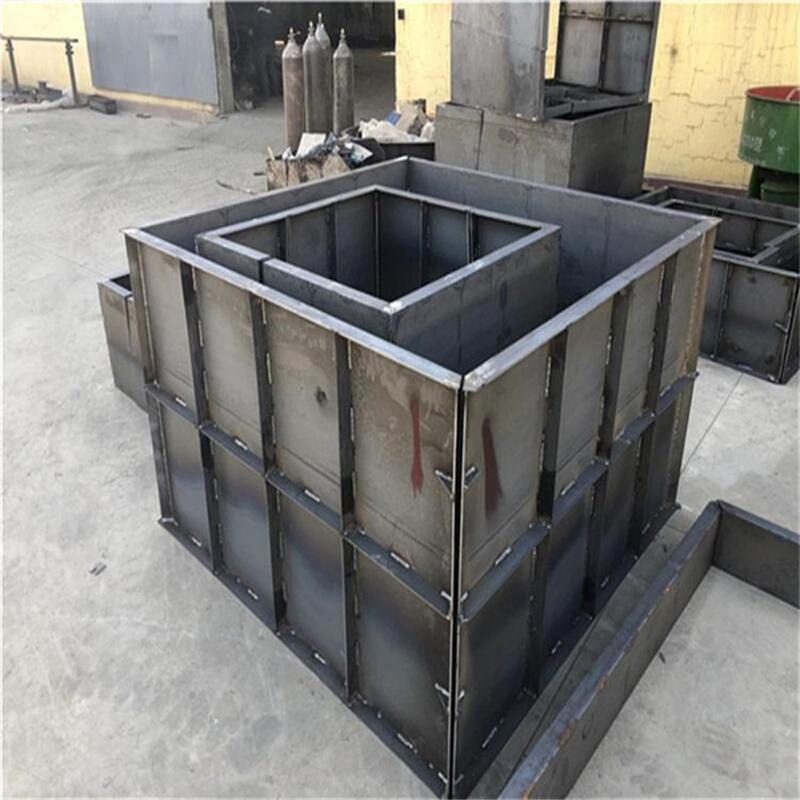

检查井模具顾名思义用这种模具生产出的水泥检查井预制件被应用于许多工程建设当

中,生产出来的检查井具有很好的使用效果,在雨水、污水的处理上起着很大的作用

,能够把这些废水很快的排放出来,在如今这个盛行环保意识的社会非常适用。这种

模具的结构分为两部分,这两部分为面板和筋板,面板可以使模具表面光滑平整,而

筋板主要是起到了一个固定的作用,使模具不易变形,能够承受住外界很多的压力。

检查井预制件的预留孔上连接着管道,管道的作用就是可以排水运水。现在随着对水

利系统的重视,检查井在排水系统中的作用越来越明显。水泥检查井模具在制作的时

候要通过切割、焊接和拼装等工艺来加工生产,根本上来说解决了以前工程生产的效

率低下问题,节约了制作时间,提高了生产效率。水泥检查井模具选用了大量的材料

进行制作,从根本上来说也延长了使用寿命,不至于使材料出现损坏的情况,这样也

方便了下的使用。

As the name suggests, the cement manhole prefabricated parts produced by

this mold are used in many engineering construction. The produced manhole

has good use effect, plays a great role in the treatment of rainwater and

sewage, and can quickly discharge these wastewater. It is very suitable in

today's society with popular environmental awareness. The structure of the

die is divided into two parts, which are panel and rib plate. The panel

can make the die surface smooth and flat, and the rib plate mainly plays a

fixed role, so that the die is not easy to deform and can withstand a lot

of external pressure.

The reserved hole of the prefabricated part of the

inspection well is connected with the pipeline, which is used for drainage

and water transportation. Now, with the attention paid to the water

conservancy system, the role of inspection wells in the drainage system is

becoming more and more obvious. The cement inspection well mold should be

processed and produced through cutting, welding and assembly, which

fundamentally solves the problem of low efficiency of previous engineering

production, saves manufacturing time and improves production efficiency.

The cement inspection well mold is made of a large number of materials,

which fundamentally prolongs the service life and will not cause damage to

the materials, which is also convenient for use in the next.

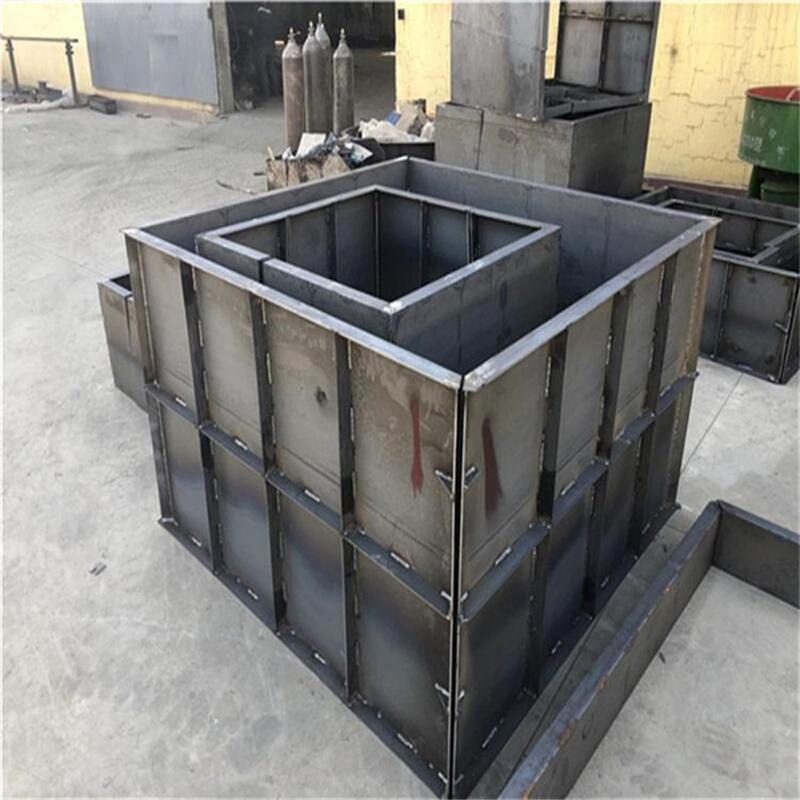

中,生产出来的检查井具有很好的使用效果,在雨水、污水的处理上起着很大的作用

,能够把这些废水很快的排放出来,在如今这个盛行环保意识的社会非常适用。这种

模具的结构分为两部分,这两部分为面板和筋板,面板可以使模具表面光滑平整,而

筋板主要是起到了一个固定的作用,使模具不易变形,能够承受住外界很多的压力。

检查井预制件的预留孔上连接着管道,管道的作用就是可以排水运水。现在随着对水

利系统的重视,检查井在排水系统中的作用越来越明显。水泥检查井模具在制作的时

候要通过切割、焊接和拼装等工艺来加工生产,根本上来说解决了以前工程生产的效

率低下问题,节约了制作时间,提高了生产效率。水泥检查井模具选用了大量的材料

进行制作,从根本上来说也延长了使用寿命,不至于使材料出现损坏的情况,这样也

方便了下的使用。

As the name suggests, the cement manhole prefabricated parts produced by

this mold are used in many engineering construction. The produced manhole

has good use effect, plays a great role in the treatment of rainwater and

sewage, and can quickly discharge these wastewater. It is very suitable in

today's society with popular environmental awareness. The structure of the

die is divided into two parts, which are panel and rib plate. The panel

can make the die surface smooth and flat, and the rib plate mainly plays a

fixed role, so that the die is not easy to deform and can withstand a lot

of external pressure.

The reserved hole of the prefabricated part of the

inspection well is connected with the pipeline, which is used for drainage

and water transportation. Now, with the attention paid to the water

conservancy system, the role of inspection wells in the drainage system is

becoming more and more obvious. The cement inspection well mold should be

processed and produced through cutting, welding and assembly, which

fundamentally solves the problem of low efficiency of previous engineering

production, saves manufacturing time and improves production efficiency.

The cement inspection well mold is made of a large number of materials,

which fundamentally prolongs the service life and will not cause damage to

the materials, which is also convenient for use in the next.