商铺名称:保定建信模具制造有限公司

联系人:冉经理()

联系手机:

固定电话:

企业邮箱:

联系地址:

邮编:

联系我时,请说是在五金机电网上看到的,谢谢!

商品详情

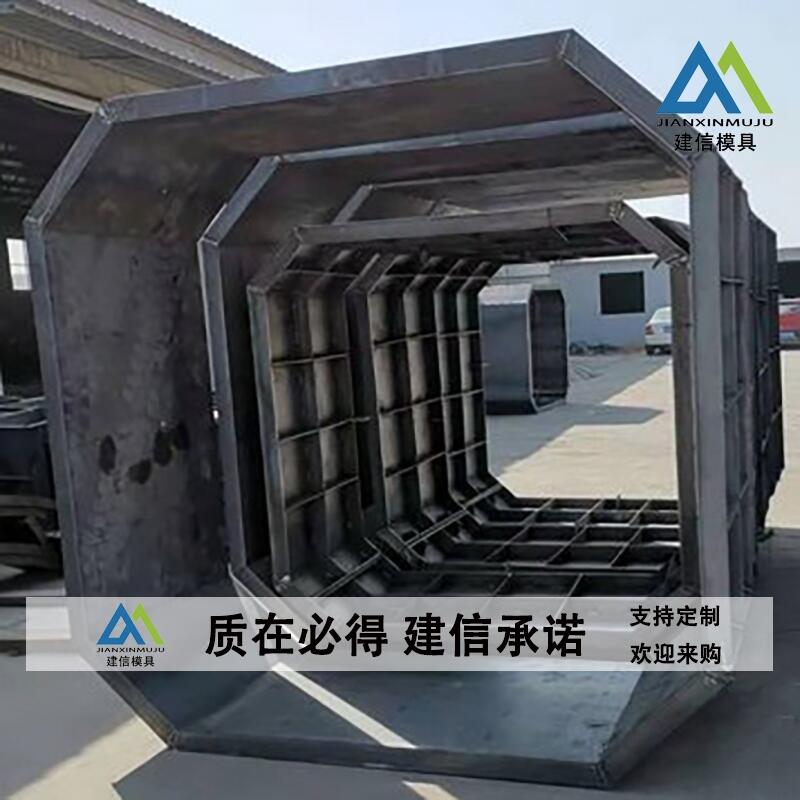

预制检查井模具、圆形井模具使用更简单,拼装和拆卸都十分方便,只需要简单地将模具上的螺丝拧

紧,检查模板间没有留有缝隙就可以注浆了,而注浆后只需要几十秒的振动时间,就可以放置在阴凉

通风的地方自然晾晒等待其凝固,这个过程基本不耗费人力,也不消耗工作时间,因为在等待模具中

混凝土完全凝固的过程中工人完全可以进行下一组的生产,有着高效快速的优势;从个性化的尺寸设

计上来看,顾客在定制圆形井模具时,可以根据自己使用的管道直径、需要的圆井宽度与厂家协商进

行定制打造的,所以使用这种模具生产出的混凝土圆井预制件都是可以满足工程需要的,由于是定制

生产也就更能满足使用和后续的配套。

Prefabricated inspection well molds and circular well molds are easier to use, and are

very convenient for assembly and disassembly. Grouting can be carried out only by simply

tightening the screws on the molds and checking that there is no gap between the molds.

After grouting, it only takes tens of seconds of vibration time to place them in a cool

and ventilated place for natural drying and wait for them to solidify. This process

basically does not consume manpower, It also does not consume working time, because in

the process of waiting for the complete solidification of concrete in the mold, workers

can carry out the next group of production, which has the advantage of high efficiency

and speed; From the perspective of personalized size design, customers can customize the

circular well mold according to their own pipe diameter and required circular well width

through consultation with the manufacturer. Therefore, the concrete circular well

prefabricated parts produced by using this mold can meet the needs of the project.

Because it is customized production, it can better meet the use and subsequent

supporting.

预制检查井模具、圆形井模具所投入生产的检查井大多数都是混凝土制造的一体化的预制件,因为用

料是客户按照自己所需要的混凝土强度,按照专业而科学的数据配比的,制作检查井时只需要将调配

并搅拌均匀的混凝土注入模具中,等待其自然成型,这样产出的预制块凝固后是自然一体的。

Most of the inspection wells put into production by prefabricating inspection well molds

and circular well molds are integrated prefabricated parts made of concrete, because the

materials are proportioned by customers according to their required concrete strength and

professional and scientific data. When making inspection wells, it is only necessary to

inject the evenly mixed concrete into the mold and wait for it to take shape naturally,

The prefabricated blocks produced in this way are naturally integrated after

solidification.

预制检查井模具、圆形井模具专门设计的一种钢材质工具,目前也被广泛地应用在城市的光纤电缆铺

设和检查方面,用途多、适用范围广,无疑是因为其独特的优势,主要体现在其高效的生产速度、个

性化的尺寸设计和更高的产品质量方面。不似传统的砖砌检查井,砖块出强度大,与水泥黏合处强度

小,正如水桶的短板才是它盛水的真实能力,所以一体化的检查井受力时也是均匀的,不存在缝隙开

裂的问题,也就更结实更耐用;二是在价格方面,利用预制检查井模具生产检查井只需要组装、刷油

、灌浆、震动、拆模五个步骤,十分简单,只需要一个工人就可以进行大规模的生产,在劳动力成本

上十分节约。预制检查井模具、圆形井模具在效率方面,每一个检查井的制作中,从注浆后到拆模前

这一段时间人力都是解放的,而这段时间工人就可以进行下一个检查井的生产,拆模时再按照注浆顺

序拆模,这样单人一天就可以生产几十个检查井预制件,节约了时间成本同时也提高了生产效率。

Prefabricated inspection well mold and circular well mold are specially designed steel

tools. At present, they are also widely used in urban optical fiber cable laying and

inspection. They have many uses and wide application range. Undoubtedly, because of their

unique advantages, they are mainly reflected in their efficient production speed,

personalized size design and higher product quality. Unlike the traditional brick

inspection well, the brick has high strength and low strength at the joint with cement.

Just like the short plate of the bucket is its real ability to hold water, so the stress

of the integrated inspection well is also uniform, there is no crack problem, so it is

stronger and more durable; Second, in terms of price, the use of prefabricated inspection

well molds to produce inspection wells only needs five steps: assembly, oil painting,

grouting, vibration and formwork removal. It is very simple. Only one worker can carry

out large-scale production, which is very economical in labor cost. In terms of

efficiency of prefabricated inspection well molds and circular well molds, during the

production of each inspection well, the manpower is liberated from the time after

grouting to the time before formwork removal, and during this time, the workers can carry

out the production of the next inspection well, and then remove the formwork according to

the grouting sequence, so that a single person can produce dozens of inspection well

prefabricated parts a day, It not only saves time and cost, but also improves production

efficiency.

紧,检查模板间没有留有缝隙就可以注浆了,而注浆后只需要几十秒的振动时间,就可以放置在阴凉

通风的地方自然晾晒等待其凝固,这个过程基本不耗费人力,也不消耗工作时间,因为在等待模具中

混凝土完全凝固的过程中工人完全可以进行下一组的生产,有着高效快速的优势;从个性化的尺寸设

计上来看,顾客在定制圆形井模具时,可以根据自己使用的管道直径、需要的圆井宽度与厂家协商进

行定制打造的,所以使用这种模具生产出的混凝土圆井预制件都是可以满足工程需要的,由于是定制

生产也就更能满足使用和后续的配套。

Prefabricated inspection well molds and circular well molds are easier to use, and are

very convenient for assembly and disassembly. Grouting can be carried out only by simply

tightening the screws on the molds and checking that there is no gap between the molds.

After grouting, it only takes tens of seconds of vibration time to place them in a cool

and ventilated place for natural drying and wait for them to solidify. This process

basically does not consume manpower, It also does not consume working time, because in

the process of waiting for the complete solidification of concrete in the mold, workers

can carry out the next group of production, which has the advantage of high efficiency

and speed; From the perspective of personalized size design, customers can customize the

circular well mold according to their own pipe diameter and required circular well width

through consultation with the manufacturer. Therefore, the concrete circular well

prefabricated parts produced by using this mold can meet the needs of the project.

Because it is customized production, it can better meet the use and subsequent

supporting.

预制检查井模具、圆形井模具所投入生产的检查井大多数都是混凝土制造的一体化的预制件,因为用

料是客户按照自己所需要的混凝土强度,按照专业而科学的数据配比的,制作检查井时只需要将调配

并搅拌均匀的混凝土注入模具中,等待其自然成型,这样产出的预制块凝固后是自然一体的。

Most of the inspection wells put into production by prefabricating inspection well molds

and circular well molds are integrated prefabricated parts made of concrete, because the

materials are proportioned by customers according to their required concrete strength and

professional and scientific data. When making inspection wells, it is only necessary to

inject the evenly mixed concrete into the mold and wait for it to take shape naturally,

The prefabricated blocks produced in this way are naturally integrated after

solidification.

预制检查井模具、圆形井模具专门设计的一种钢材质工具,目前也被广泛地应用在城市的光纤电缆铺

设和检查方面,用途多、适用范围广,无疑是因为其独特的优势,主要体现在其高效的生产速度、个

性化的尺寸设计和更高的产品质量方面。不似传统的砖砌检查井,砖块出强度大,与水泥黏合处强度

小,正如水桶的短板才是它盛水的真实能力,所以一体化的检查井受力时也是均匀的,不存在缝隙开

裂的问题,也就更结实更耐用;二是在价格方面,利用预制检查井模具生产检查井只需要组装、刷油

、灌浆、震动、拆模五个步骤,十分简单,只需要一个工人就可以进行大规模的生产,在劳动力成本

上十分节约。预制检查井模具、圆形井模具在效率方面,每一个检查井的制作中,从注浆后到拆模前

这一段时间人力都是解放的,而这段时间工人就可以进行下一个检查井的生产,拆模时再按照注浆顺

序拆模,这样单人一天就可以生产几十个检查井预制件,节约了时间成本同时也提高了生产效率。

Prefabricated inspection well mold and circular well mold are specially designed steel

tools. At present, they are also widely used in urban optical fiber cable laying and

inspection. They have many uses and wide application range. Undoubtedly, because of their

unique advantages, they are mainly reflected in their efficient production speed,

personalized size design and higher product quality. Unlike the traditional brick

inspection well, the brick has high strength and low strength at the joint with cement.

Just like the short plate of the bucket is its real ability to hold water, so the stress

of the integrated inspection well is also uniform, there is no crack problem, so it is

stronger and more durable; Second, in terms of price, the use of prefabricated inspection

well molds to produce inspection wells only needs five steps: assembly, oil painting,

grouting, vibration and formwork removal. It is very simple. Only one worker can carry

out large-scale production, which is very economical in labor cost. In terms of

efficiency of prefabricated inspection well molds and circular well molds, during the

production of each inspection well, the manpower is liberated from the time after

grouting to the time before formwork removal, and during this time, the workers can carry

out the production of the next inspection well, and then remove the formwork according to

the grouting sequence, so that a single person can produce dozens of inspection well

prefabricated parts a day, It not only saves time and cost, but also improves production

efficiency.