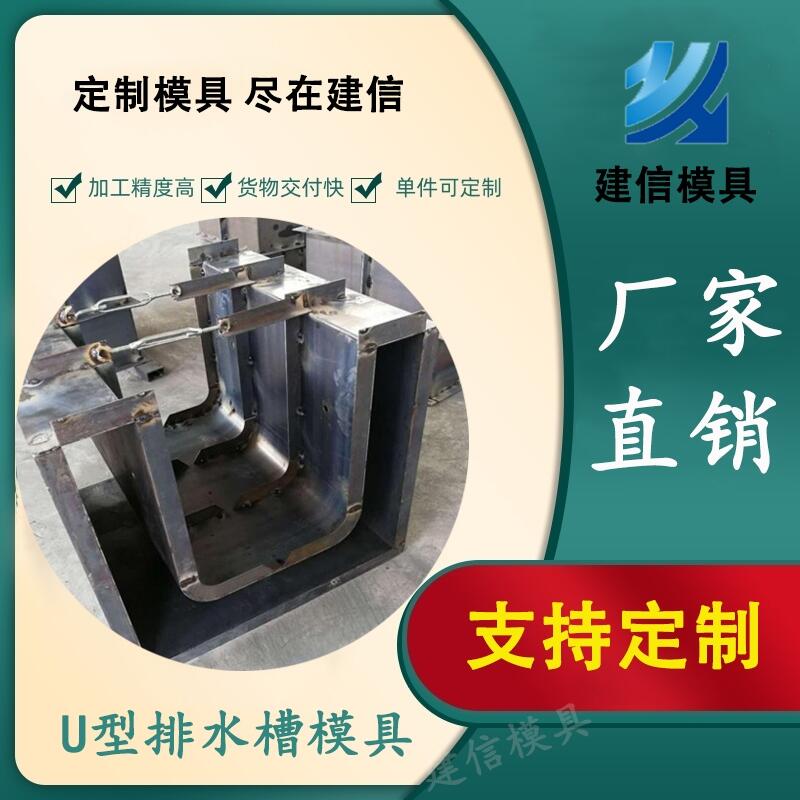

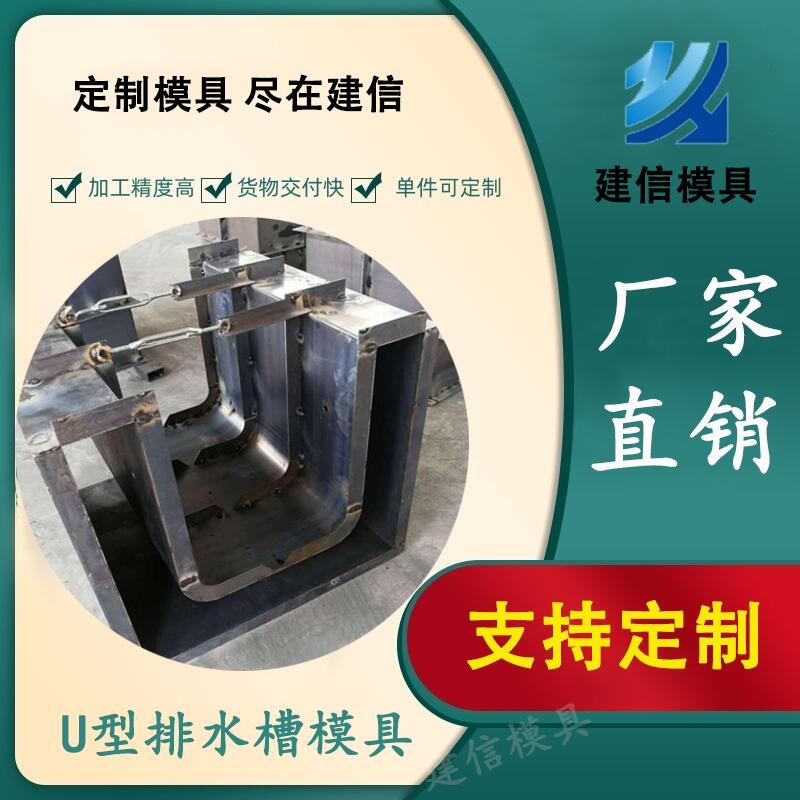

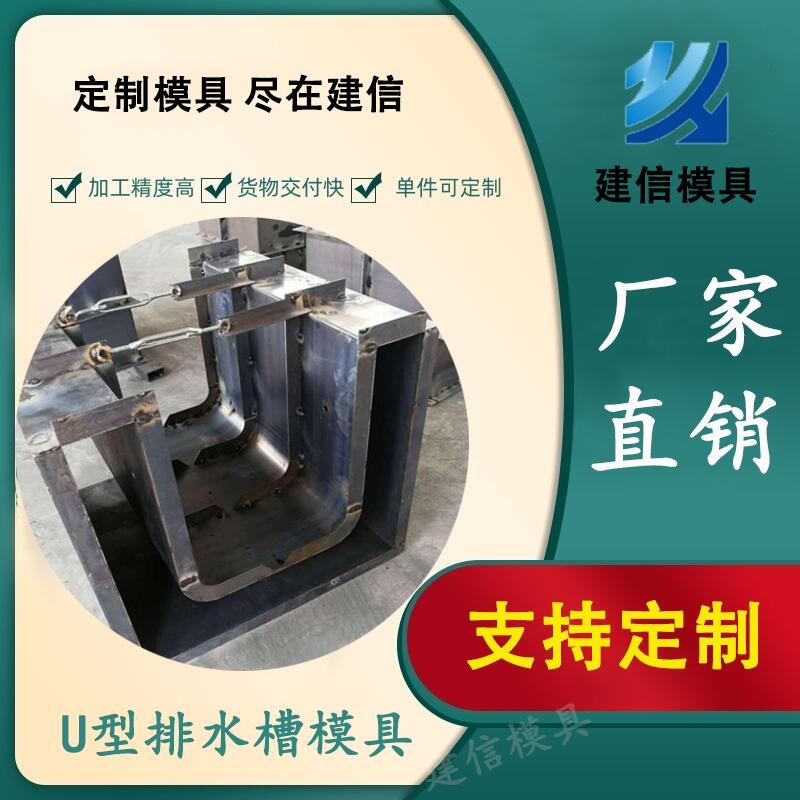

商铺名称:保定建信模具制造有限公司

联系人:冉经理()

联系手机:

固定电话:

企业邮箱:

联系地址:

邮编:

联系我时,请说是在五金机电网上看到的,谢谢!

商品详情

流水槽模具原材料一般有塑料注塑成型与钣金钢模具成型两种,水泥流水槽沟盖板塑料模具采用聚丙烯塑料颗粒状经过注塑机高温处理注入预先准备好的流水槽沟盖板模腔当中,待经过冷却处理之后成型流水槽沟盖板模具;水泥流水槽沟盖板钢模具以3-8毫米的铁板经过卷曲,裁切,造型,加固,焊接,拼装,打磨等多道手续制作而成。The raw materials of the gutter mold generally include plastic injection molding and sheet steel mold molding. The plastic mold of the cement gutter cover plate adopts polypropylene plastic particles, which are injected into the pre prepared gutter cover plate mold cavity after high temperature treatment by the injection molding machine, and the gutter cover plate mold is bed after cooling treatment; The steel mould for the cover plate of cement gutter is made of 3-8mm iron plate through crimping, cutting, modeling, reinforcement, welding, assembly, grinding and other procedures.

流水槽模具在每次脱模加工完成后都是要停止清洁的,模具需求屡次来循环运用,并且相对来说在停止加工的时分一定要留意好维护工作,只要这样才干够让流水槽更为顺利的被制造出来,自然在加工完成后的预制件也能够停止施工。但是目前来说流水槽在日常生活中的运用还是比拟频繁的,不像其他的预制件有着规则的运用范围,流水槽的话有着各种的尺寸,目前的公园建立、城市绿化或者是道路建立等等,都是会用到流水槽的。After each demoulding process, the gutter mold should be stopped cleaning. The mold needs to be recycled repeatedly, and relatively speaking, when the processing is stopped, we must pay attention to the maintenance work. Only in this way can the gutter be manufactured more smoothly, and naturally the construction of prefabricated parts after the processing can be stopped. However, at present, the use of gutters in daily life is relatively frequent. Unlike other prefabricated parts with regular application scope, gutters have various sizes. At present, gutters will be used in park construction, urban greening or road construction.

流水槽模具在每次脱模加工完成后都是要停止清洁的,模具需求屡次来循环运用,并且相对来说在停止加工的时分一定要留意好维护工作,只要这样才干够让流水槽更为顺利的被制造出来,自然在加工完成后的预制件也能够停止施工。但是目前来说流水槽在日常生活中的运用还是比拟频繁的,不像其他的预制件有着规则的运用范围,流水槽的话有着各种的尺寸,目前的公园建立、城市绿化或者是道路建立等等,都是会用到流水槽的。After each demoulding process, the gutter mold should be stopped cleaning. The mold needs to be recycled repeatedly, and relatively speaking, when the processing is stopped, we must pay attention to the maintenance work. Only in this way can the gutter be manufactured more smoothly, and naturally the construction of prefabricated parts after the processing can be stopped. However, at present, the use of gutters in daily life is relatively frequent. Unlike other prefabricated parts with regular application scope, gutters have various sizes. At present, gutters will be used in park construction, urban greening or road construction.

在线询盘/留言