商铺名称:保定建信模具制造有限公司

联系人:冉经理()

联系手机:

固定电话:

企业邮箱:

联系地址:

邮编:

联系我时,请说是在五金机电网上看到的,谢谢!

商品详情

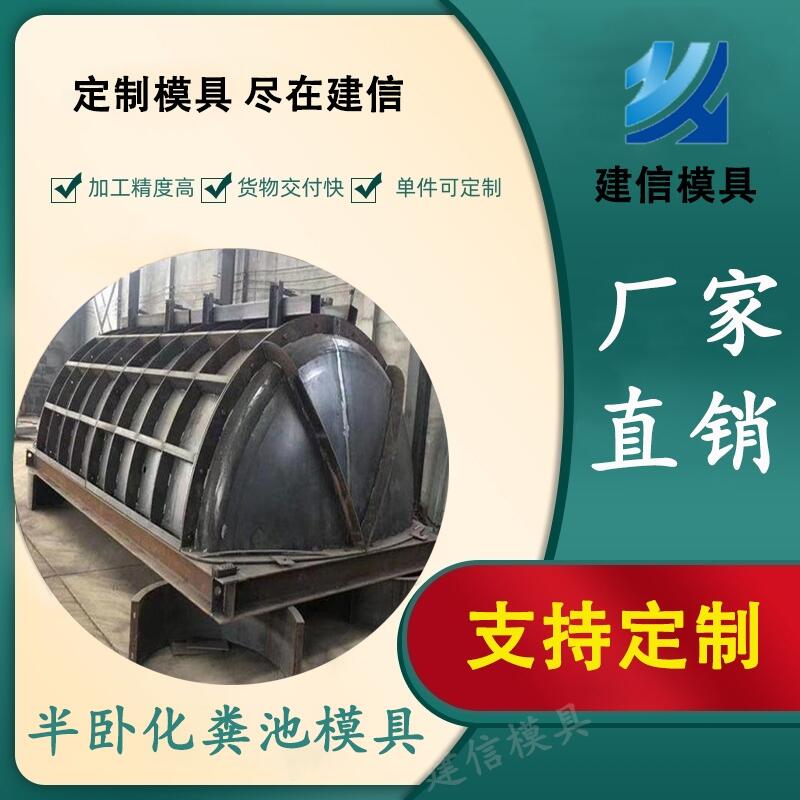

从罐式化粪池模具的内部结构上来看,他的制作方式主要是以焊接为主,他的严密性较强,不容易发生泥浆泄露的情况,相比与之前的立式化粪池模具来看,该模具的结构复杂,但是生产的预制件的容积非常大,能够长时间使用The mold of tank septic tank is made according to the specification of septic tank. Generally, the mold shall be made according to the length, height, diameter, wall thickness and other data of the mold. The size selection of the mold is very flexible. During specific construction, the internal and external mold parts of the mold shall be assembled together, and then the mixed concrete shall be poured from the grouting opening of the mold, When removing the bwork, you only need to open two copies of the outer bwork.。

卧式化粪池模具还需将预留孔考虑在内,设计完成后严格按照既定的规格进行生产,电子操控机床,对钢板进行切割,在人工对钢板进行焊接,将切割好的筋板焊接在面板上,面板主要是起固定原料的作用,筋板主要是加强模具的抗压能力,利用卧式化粪池模具生产时,需要用混凝土进行灌装,这会对模具产生很大的压力,如果模具不具备一定的抗压能力,可能会发生变形和破裂,浪费原料,同时筋板也可以使模具保持固定的形状,不易发生改变,这在保存时也是很重要的。不同规格的卧式化粪池模具所使用的钢板厚度是不同的,在保证模具能够生产合格的产品的同时,节约了成本,回馈给顾客,用更低的价格,得到更好的产品

罐式化粪池模具在使用时需要将配套的混凝凝土进行填充使用,但是要注意将混凝土进行震动处理,这样才能将混凝土内产生的多余的气泡排出,是混凝土在凝固后整体更加坚硬,使用性能更强,但是要注意将使用完的模具用清洁剂进行清理,这样是模具的使用次数提升,将模具用叉车转移到仓库内进行保存,为了放方便统计要做好入库登记。

When the tank septic tank mold is used, it is necessary to fill the supporting concrete, but pay attention to the vibration treatment of the concrete, so as to discharge the excess bubbles generated in the concrete. The concrete is harder and has stronger service perbance after solidification, but pay attention to clean the used mold with detergent, In this way, the use times of molds are increased. The molds are transferred to the warehouse with forklift for storage. In order to facilitate statistics, warehousing registration shall be done.

在线询盘/留言